Honeycomb Ceramics O3 Ozone Decomposition Catalyst/Ceramic Honeycomb Catalyst for Ozone Removal

Description

Basic Info.

| Usage | Positive Catalyst, Negative Catalyst |

| Effect Size | Primary Catalysts |

| Manufacturing Method | Method of Precipitation |

| Application Industry | Industry |

| Packing | Carton Box with Plastic Frame / Bubble Shock Absor |

| Moisture | 3% Max |

| Ozone Treatment Efficiency | 100% |

| Recommended Space Velocity | 1X10^4 to 8X10^4 |

| Bulk Density | 0.5 G/Ml |

| Size | 100*100*50mm or Customize |

| Customization | Available |

| Color | Black |

| Transport Package | Iron Barrel with Plastic Lining; |

| Specification | pellet, granule, powder, honeycomb |

| Trademark | Minstrong |

| Origin | China |

| HS Code | 38151900 |

| Production Capacity | 1000000000 Pieces Year |

Product Description

Product Description

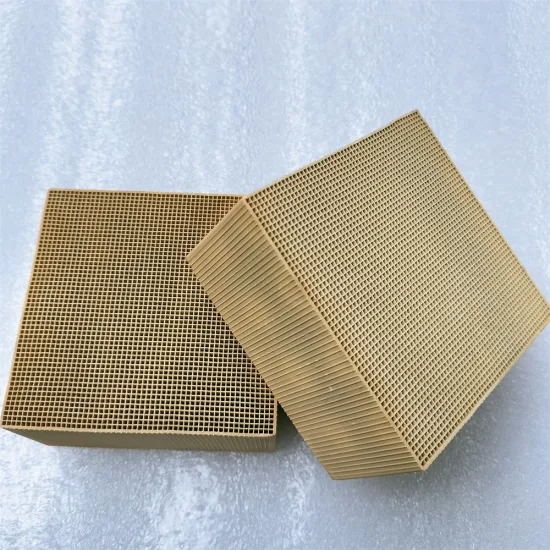

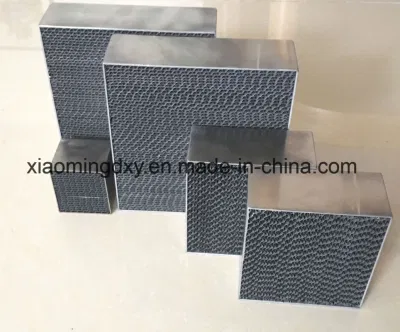

Minstrong ozone destruction catalyst can efficiently decompose ozone into oxygen, eliminate ozone odor, and achieve exhaust emission standards. Minstrong uses chemical synthesis method to manufacture active components, and precisely controls each process parameter of the synthesis reaction. Through different molding methods, Minstrong processes the ozone catalyst into different forms and shapes, such as powder, columnar pellet, granular, honeycomb, etc., to meet the ozone destruction requirements under different conditions.Minstrong honeycomb ozone destruction catalyst has the advantages of light weight, low resistance, high space velocity, and can efficiently remove ozone in a large space.The types of Minstrong ozone honeycomb destruction catalysts include aluminum honeycomb, activated carbon honeycomb, ceramic honeycomb and stainless steel honeycombProduct Parameters

| Ozone Destruction Catalyst Technical Data | |

| Apperance | Black |

| Specification | 100*100*50mm or customize |

| Space Velocity | 5000-100000 /h |

| Moisture | 3% max |

| Bulk Density | 0.5 ± 0.05 g/ml |

| Ozone decomposition efficiency | Can reach 100% |

Size Specification Available

| Type | Typical Sizes | Other Sizes |

| Pellet | Diameter 1.1 mm | All sizes from pellet 1.1mm to 9mm can be produced, such as pellet diameter 2mm, 4mm, etc. |

| Diameter 3 mm | ||

| Diameter 5 mm | ||

| Diameter 9 mm | ||

| Granule | 4-8 Mesh | Different granule sizes can be produced as your request. |

| 8-14 Mesh | ||

| 6-12 Mesh | ||

| 10-16 Mesh | ||

| 12-20 Mesh | ||

| Powder | Finer than 80 Mesh | Finer than 80 Mesh |

| Spherality Ball | Diameter 2mm-10mm | Produced as your request. |

| Honeycomb | 100x100x50mm | Produced as your request. |

| Note: Catalyst specification parameters can be customized according to requirements. | ||

Recommend Commodities

Minstrong has honeycomb, pellet columnar, irregular granular, powder and spherality ball type for different working conditions. Minstrong also can customize different size and data as your request.Packaging & Shipping

General Packing: carton box with plastic frame / Bubble shock absorber, Packing based on user's needs.For quantity below 2 tons / 5000 pieces, Minstrong can deliver the catalyst within 7 days.Shipping Port: Shanghai/other port as requestAir transportation, ocean transportation, railway transportation and truck transportation are available.Our Advantages

1) The raw materials and production process of the product are completely independent and controllable, and can be supplied stably for long-term;2) Anual output higher than 1200 tons;3) Minstrong can provide you with professional catalyst application consultation, and design a reasonable exhaust gas treatment solution based on Minstrong's high-performance catalyst;4) Minstrong can guide you in the design of process and equipment for free;5) Minstrong can provide you with the construction of test equipment, as well as the design, manufacture and installation of supporting catalytic reactors;6) Minstrong can provide you with on-site catalyst loading and debugging guidance.Company Profile

Minstrong begin catalyst research and production since 1981. We believe, only focus can be professional.Minstrong Technology Co., Ltd, is a high-tech enterprise with high-performance catalyst research and development and manufacturing as its core business. Minstrong products involve Hopcalite catalysts, carbon monoxide catalysts, ozone destruction catalysts, ozone filter destructor, VOC catalysts, and active manganese dioxide catalysts, activated copper oxide catalysts and other catalyst materials. The catalyst materials are are exported to all over the world, widely used in industrial tail gas treatment, water treatment, health care, electronic information, semiconductor and other industries.

Minstrong has established a complete catalyst research and development system and production process control system.The production process is completely independent and controllable, the product quality is stable.

Minstrong Innovation Center has multiple laboratories and pilot workshops. Based on advanced technology and rich experience, Minstrong can provide you with reliable catalysts and help you achieve the best application of catalysts.

Questions You May Care About

1) Can I get sample?In order to help you know our products better, our factory would like to offer free sample after mutual communication.2) How to replace catalysts of other brands?Minstrong catalyst has excellent performance and low bulk specific gravity. You can achieve the same effect by replacing other brand catalysts with the same volume, and you can save 1/3 of the cost.3) How do I determine the specification and dosage of the catalyst?According to your working conditions, we can select catalysts with appropriate specifications and calculate reasonable dosages.4) How can I compare the cost of catalyst?Catalysts are not consumable materials, and are generally calculated according to volume. It is necessary to calculate the comprehensive cost of catalysts based on important factors such as specific gravity, catalytic efficiency, and service life, and at the same time assess the technical and service capabilities of suppliers to prevent after-sales risks5) What should I do if I don't know how to use the catalyst?We will design a reasonable process flow according to your working conditions, and provide you with one-stop services such as catalyst selection, test plan formulation, device design and manufacture, and on-site commissioning.

Thank you for your patient reading! We welcome your inquiry.

Prev: 6

Our Contact

![[Qisong] Square Metallic Honeycomb Substrate for Industrial Purifying System](/uploads/s/d9d577e2dcef453d8b6922c4cec2ee44.webp)

![[Qisong] China Auto Parts Honeycomb Metallic Monolith Substrate for Catalytic Converter](/uploads/s/9e057ff538af400eae4ea4d1475c380f.webp)

![[Qisong] Metallic Honeycomb Substrate for Vehicle](/uploads/s/54d8cbce014f4bbcb51928ca6a7d68a8.webp)