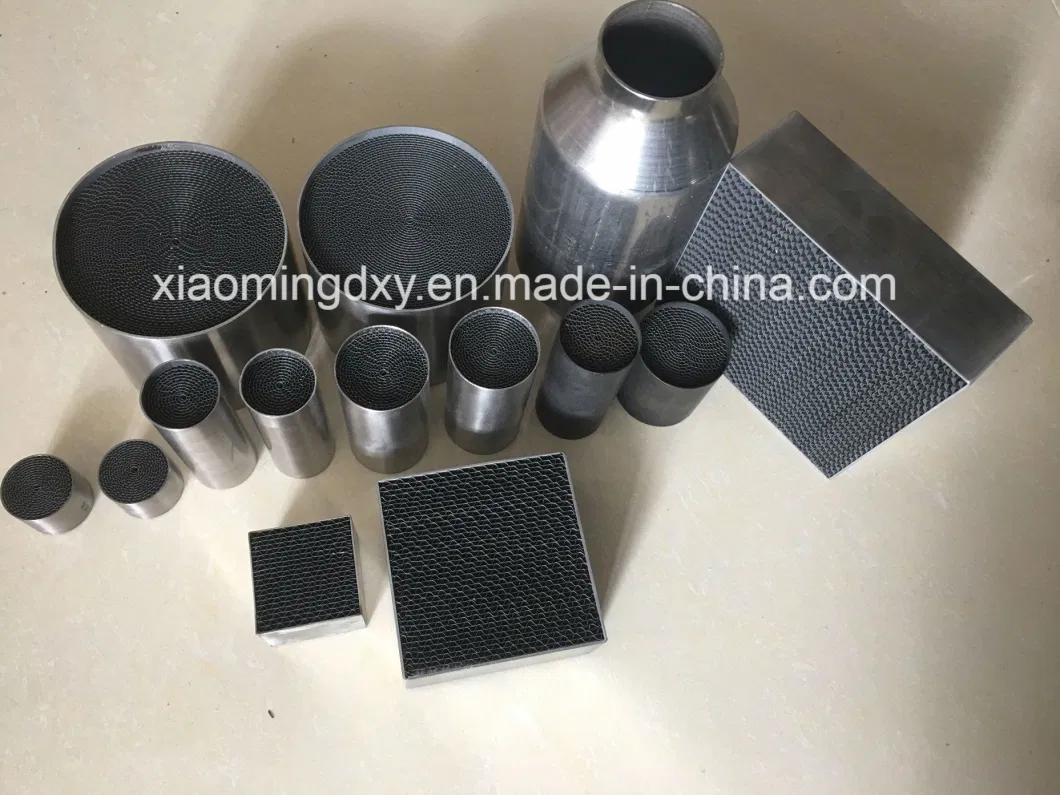

Euroiv Metal Honeycomb Substrate Catalytic Converter Substrate

Metallic substrate is with the advantages of fast burning, small volume, high mechanical strength, prominent heat-resist

Description

Basic Info.

| Model NO. | MHS |

| Automobile Chassis Noise | The Brake Noise |

| Component | Catalytic Converter |

| Main Market | Europe |

| Width(mm) | 10-250 |

| Thickness(mm) | 0.04-0.1 |

| Max Service Temperature | 1250°c |

| Max Working Temperature | 1100°c |

| Cell | 100-600cpsi |

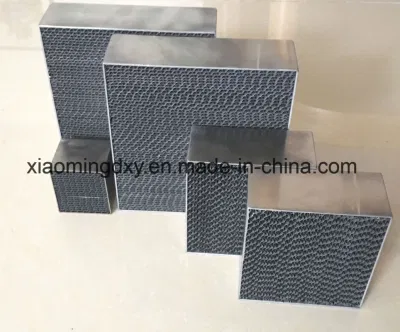

| Shape | Round/Square/Rectangular |

| Material | SS304, SS316 |

| Transport Package | Wooden Box and Pallet/Packed as Customers′ Need |

| Specification | all size |

| Trademark | DXY |

| Origin | China |

| HS Code | 84213990 |

| Production Capacity | 100, 000pieces/Month |

Product Description

Metallic substrate is with the advantages of fast burning, small volume, high mechanical strength, prominent heat-resistance, etc. It is widely used in exhaust gas purification, especially for motorbike, vehicle and so on. High strength complex substrate plus big surface area and active element of noble metal could lower down pollutant value of motorcycle exhaust efficiently, such as CO, HC, NOX etc. And such kind of catalyst is of excellent catalytic activity and durability that could reach Euro emission standard 3, meet requirement and have approval of EPA and E-Mark.*Catalyst type: Complex catalyst of noble metal (Pt, Pd, Rh) plus rare earth complex catalyst

*Catalytic substrate: Metal substrate and honeycomb ceramic substrate

*Fantastic coating fastness and stably and long-term catalyst ability

*Advanced technic of substrates making and canning, ensuring depandable resistance heat shocks and stability of equipment

*Various kinds of specifications and types, customized products as per clients specific requirement and technology data

Major technical parameters:

Substrate: Metal honeycomb substrate (Fe-Cr-Al alloy)

Light-off temperature: CO≤ 200° C, HC≤ 200° C, NOX≤ 200° C

Coating losing rate ≤ 3%

Conversion rate: CO≥ 90%, HC≥ 90%, NOX≥ 80%

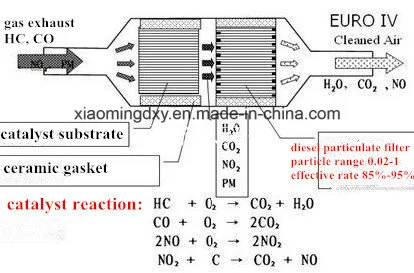

Working principle:

*Catalytic converter is a device used to reduce the toxicity of emissions from an internal combustion engine

*Reduction of nitrogen oxides to nitrogen and oxygen:

2NOx xO2 + N2

*Oxidation of carbon monoxide to carbon dioxide:

2CO + O2 2CO2

*Oxidation of un-burnt hydrocarbons (HC) to carbon dioxide and water:

CxH2x+2 + [(3x+1)/2]O2 xCO2 + (x+1)H2O

Advantages:

*Fantastic coating fastness and stable and long-termed catalyst ability

*Advanced technic of substrates making and canning, ensuring dependable resistance heat shocks and stability of equipment

Remark: We can supply Metallic Substrate coated with noble metals of Pt, Pd and

Rh. We also supply Metallic Substrate without noble metals

| Mantle | Matrix | Brazing | |

| Ferritel (SUS444, SUS441, SUS430) or Austenitic heat resistant stainless steel (SUS304) | Fe-Cr-Al with RE, Zr/Ti additions high temperature oxidation resistant special alloy Domestic FeCrAl(2073/216) Import FeCrAl(1.4725/1.4767) | Nickel base alloy |

| Shape | Shell size(mm) | Core size(mm) | Cell density (CPSI) |

| Rotundity | Ø 30x22 | Ø 28X20 | 100/200/300/400 |

| Rotundity | Ø 35x20 | Ø 33X20 | 100/200/300/400 |

| Rotundity | Ø 35x30 | Ø 33x30 | 100/200/300/400 |

| Rotundity | Ø 35x40 | Ø 33x40 | 100/200/300/400 |

| Rotundity | Ø 35x50 | Ø 33x50 | 100/200/300/400 |

| Rotundity | Ø 35x60 | Ø 33x60 | 100/200/300/400 |

| Rotundity | Ø 35 x 70/100/130 | Ø 33 x 60/90/120 | 100/200/300/400 |

| Rotundity | Ø 42 x 70/100/130 | Ø 40 x 60/90/120 | 100/200/300/400 |

| Rotundity | Ø 45 x 70/100/130 | Ø 43 x 60/90/120 | 100/200/300/400 |

| Rotundity | Ø 63.5 x 85/100/130 | Ø 60.5 x 74.5/90/120 | 200/300/400 |

| Rotundity | Ø 73 x 70/100/130 L | Ø 70 x 60/90/120 | 200/300/400 |

| Rotundity | Ø 93 x 70/100/130 | Ø 90 x 60/90/120 | 200/300/400 |

| Rotundity | Ø 100.3 x 100/130 | Ø 98.3 x 90/120 | 600 |

| Rotundity | Ø 144 x 150/152.4 | Ø 142 x 140/142.4 | 200/300/400 |

| Rotundity | Ø 190 x 200 | Ø 188 x 190 | 200/300/400 |

| Rotundity | Ø 420 x 100/130 | Ø 416 x 90/120 | 300/400 |

| Race track | 123x63x85 | 120x60x75 | 200/300 |

| Race track | 123x63x100 | 120x60x90 | 200/300 |

| Race track | 78.5x52x104 | 76.5x50x90 | 200/300 |

Prev: Honeycomb Cordierite Ceramic Catalyst with Mn and Cu for Voc Gas Purification

Next: Metal Honeycomb Catalyst Substrate for Catalytic Converters

Our Contact

Send now

![[Qisong] Square Metallic Honeycomb Substrate for Industrial Purifying System](/uploads/s/d9d577e2dcef453d8b6922c4cec2ee44.webp)

![[Qisong] China Auto Parts Honeycomb Metallic Monolith Substrate for Catalytic Converter](/uploads/s/9e057ff538af400eae4ea4d1475c380f.webp)

![[Qisong] Metallic Honeycomb Substrate for Vehicle](/uploads/s/54d8cbce014f4bbcb51928ca6a7d68a8.webp)