Auto&Motorcycle Exhaust System Metal Honeycomb Substrate

We mainly produce Metal Catalytics and Ceramic Catalytics for Auto and Motorcycle exhaust system, like Honeycomb metal s

Description

Basic Info.

| Model NO. | HMS |

| Automobile Chassis Noise | Transmission Noise |

| Component | Catalytic Converter |

| Main Market | North America |

| Max Working Temperature | 1100°c |

| Width(mm) | 10-250 |

| Coefficient of Line Expansion | 14.7 |

| Density(g/cm3) | 7.16 |

| Max Service Temperature | 1250°c |

| Cell | 100-600cpsi |

| Thickness(mm) | 0.04-0.1 |

| Usage | as Catalyst Used in Automobile/Motorcycle |

| Material | SS304, SS316, Fe-Cr-Al Alloy |

| Transport Package | Wooden Box and Pallet/Packed as Customers′ Need |

| Specification | Diameter<120mm/Diameter<200mm, etc |

| Trademark | DXY |

| Origin | China |

| HS Code | 84213990 |

| Production Capacity | 100, 000pieces/Month |

Product Description

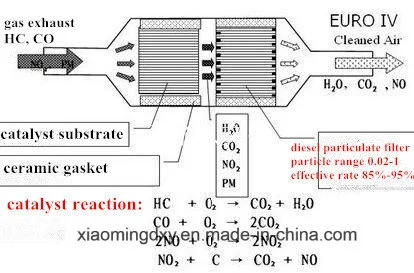

We mainly produce Metal Catalytics and Ceramic Catalytics for Auto and Motorcycle exhaust system, like Honeycomb metal substrate catalytic converter. Metallic substrate is with the advantages of fast burning, small volume, high mechanical strength, prominent heat-resistance, etc. It is widely used in exhaust gas purification, especially for motorbike. High strength complex substrate plus big surface area and active element of noble metal could lower down pollutant value of motorcycle exhaust efficiently, such as CO, HC, NOX etc...And such kind of catalyst is of excellent catalytic activity and durability that could reach Euro emission standard IV, meet requirement as per customers' requests. Metallic substrate should be pretreated in order to generate a transition layer which is required to solve the mismatched heat expansion between metallic substrate itself and the active layer. On the transition layer, it is coated with rare earth catalyst, while in active layer is coated with noble metal like PT, Pd, Rh. When the engine exhaust passing through the three-way catalytic converter the elements of CO would be oxidized into CO2, the HC is turned into H2O and CO2, while the NOX is deoxidized into nitrogen. The catalytic converter substrate is made of metal honeycomb with stainless steel crust and Fe-Cr-Al honeycomb body. It is a critical part of motorcycles and off-road engines to make the exhaust emission meet government standard.

Features:

*Low thermal expansion

*High surface area

*Long-term durability performance

*Low pressure drop

*Good thermal shock resistance

*Combined with the EGR systems to help different vehicles to satisfy emission standard

*Low light-off temperature

*Excellent adhesion between wash-coat and susbstrate with netty structure

Usage:

For exhaust system of auto engine, like Honda, Suzuki, Toyato, BMW, etc. And Diesel engine, like farm machinery and construction machinery: Tiller, Harvester, Rice transplanter, Planter, Rice mill, Weeder, Thresher, hoisting machinery, excavator, Reinforced concrete machinery.

Durability:

Metal catalyst: 100, 000 KM. However, Ceramic catalyst: 80, 000 KM

Specification:

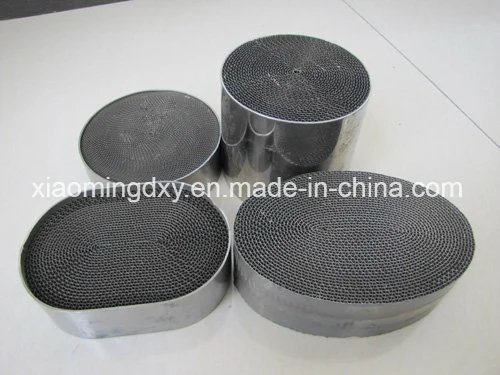

*cylinder/round shape, Size: Dia 110mm~155mm, Hight: 40mm~150mm, Cell: 100~600CPSI

Like: Dia 110*110 (Inner hight 80)mm/ 200CPSI

Dia 120*130 (Inner hight120)mm/ 400CPSI

These sizes are part of our metal catalysts, more sizes and specifications can be customized as per your engine.

| Test Result for EU- III | Emission Result, g/km | |||

| HC | CO | NOx | ||

| EU- III Standard | 0.8 | 2 | 0.15 | |

| Displacement | Item | |||

| 4 Stroke 150CC Scooter | Original Emission | 1.8 | 10.68 | 0.24 |

| With Two Catalytics | 0.19 | 1.74 | 0.09 | |

| 4 Stroke 125CC Scooter | Original Emission | 2.72 | 7.36 | 0.7 |

| With Two Catalytics | 0.14 | 0.94 | 0.13 | |

| 4 Stroke 110CC Cub | Original Emission | 0.43 | 2.47 | 0.12 |

| With One Catalytic ( without SAI ) | 0.21 | 1.16 | 0.04 | |

| 4 Stroke 150CC EFI Engine | With One Catalytic ( without SAI ) | 0.23 | 1.08 | 0.1 |

| 4 Stroke 300CC EFI Engine | With One Catalytic ( without SAI ) | 0.19 | 1.4 | 0.11 |

| Shape | Shell size(mm) | Core size(mm) | Cell density (CPSI) |

| Rotundity | Φ 30×22 | Φ 28×20 | 100/200/300/400 |

| Rotundity | Φ 35×20 | Φ 33×20 | 100/200/300/400 |

| Rotundity | Φ 35×30 | Φ 33×30 | 100/200/300/400 |

| Rotundity | Φ 35×40 | Φ 33×40 | 100/200/300/400 |

| Rotundity | Φ 35×50 | Φ 33×50 | 100/200/300/400 |

| Rotundity | Φ 35×60 | Φ 33×60 | 100/200/300/400 |

| Rotundity | Φ35 × 70/100/130 | Φ33 × 60/90/120 | 100/200/300/400 |

| Rotundity | Φ42 × 70/100/130 | Φ40 × 60/90/120 | 100/200/300/400 |

| Rotundity | Φ45 × 70/100/130 | Φ43 × 60/90/120 | 100/200/300/400 |

| Rotundity | Φ63,5 × 85/100/130 | Φ60,5 × 74,5/90/120 | 200/300/400 |

| Rotundity | Φ73 × 70/100/130 L | Φ70 × 60/90/120 | 200/300/400 |

| Rotundity | Φ93 × 70/100/130 | Φ90 × 60/90/120 | 200/300/400 |

| Rotundity | Φ100,3 × 100/130 | Φ98,3 × 90/120 | 600 |

| Rotundity | Φ144 × 150/152,4 | Φ142 × 140/142,4 | 200/300/400 |

| Rotundity | Φ190 × 200 | Φ188 × 190 | 200/300/400 |

| Rotundity | Φ420 × 100/130 | Φ416 × 90/120 | 300/400 |

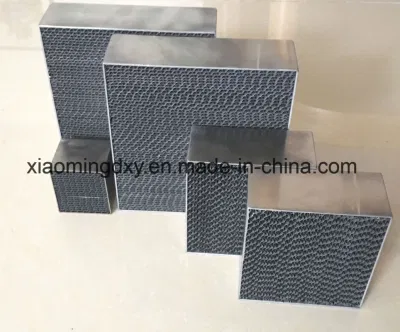

| Race track | 123×63×85 | 120×60×75 | 200/300 |

| Race track | 123×63×100 | 120×60×90 | 200/300 |

| Race track | 78,5×52×104 | 76,5×50×90 | 200/300 |

Next: Manufacturer Supplier for Subaru Forester 2.0t 2015 Catalytic Converter Middle Part Exhaust Autopart

Our Contact

Send now

![[Qisong] Square Metallic Honeycomb Substrate for Industrial Purifying System](/uploads/s/d9d577e2dcef453d8b6922c4cec2ee44.webp)

![[Qisong] China Auto Parts Honeycomb Metallic Monolith Substrate for Catalytic Converter](/uploads/s/9e057ff538af400eae4ea4d1475c380f.webp)

![[Qisong] Metallic Honeycomb Substrate for Vehicle](/uploads/s/54d8cbce014f4bbcb51928ca6a7d68a8.webp)